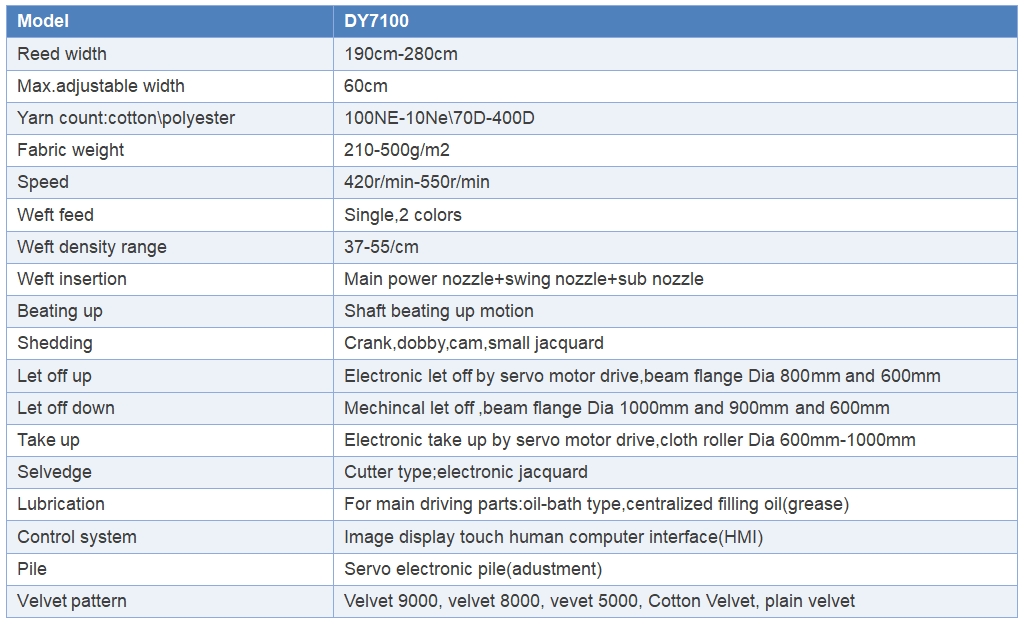

Flexible Velvet Weaving Machine With Selvage Jacquard

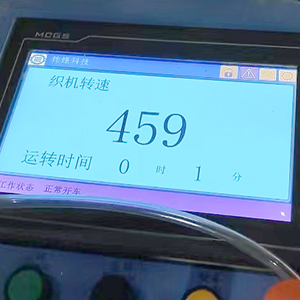

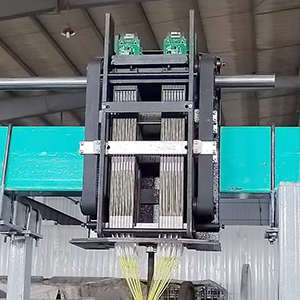

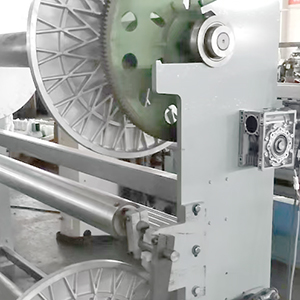

We develops and manufactures highly productive, face-to-face velvet weaving machines for plain velvet in pile widths up to 2.8 meters and pile height up to 6 mm . It is a fully electronic machine which gives maximum flexibility. Servo drive technology is used, which allows for quick quality changes and easy to adjustment on the HMI touch screen. the velvet weaving machines are controlled by powerful electronics with boosted performance for faster response and higher operating speed.