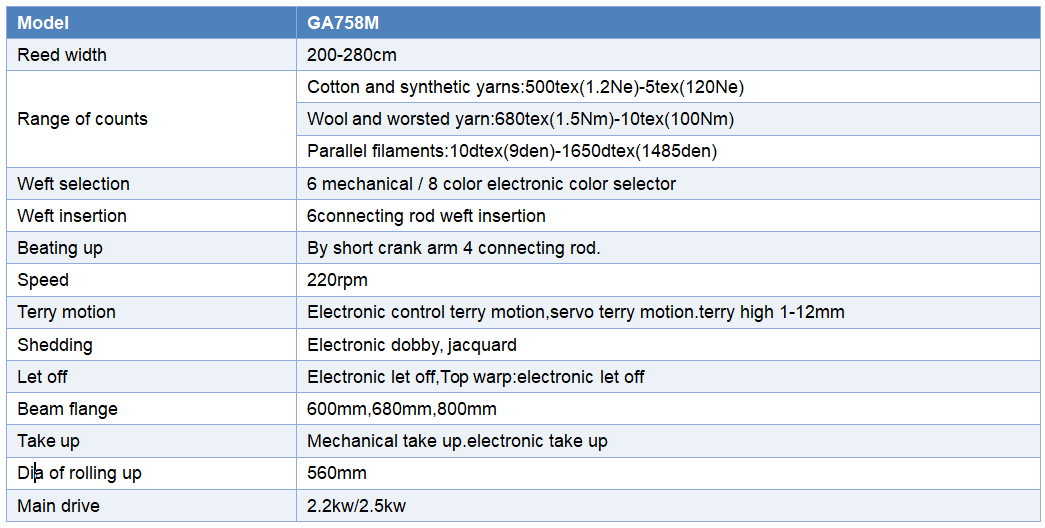

1.This machine adopts computer programming control,high degree of automation.

2.Double touch terry mechanism unique or servo-mechanism, and can weave the level terry loop,weave type terry loop,and reed reliable self-locking,prevent dilute microgroove.

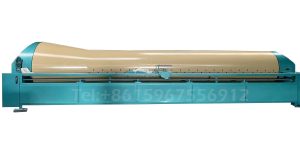

3.Terry beam by using electronic warp tension detecting mechanism, the warp tension always keep uniform.

4.Weaving satin by cramming motion, electromagnetic clutch,brake alternate control,or by a servo take up,servo warp,short reaction time and accuracy.

5.Terry loop device,adopts electromagnet signal driving cam mechanism and achieve the terry objective, the device is stable and good reliability.

6.Electronic control USB interface to computer programming control circuit, control dobby, terry raising color selection, let off, take up and other function.

7.Active electronic let off,electronic control stop feeding device,tension in weaving wide edge stain towel process more stable.

8.Active electronic let off control system LCD display function simple operation.

9.Top beam by using double tension structure, with sensor double protection and frequency control motor complete terry warp feeding.

10.High speed electronic eight color selection is controlled by the cam color selection lever, suitable for a variety weft yarn.