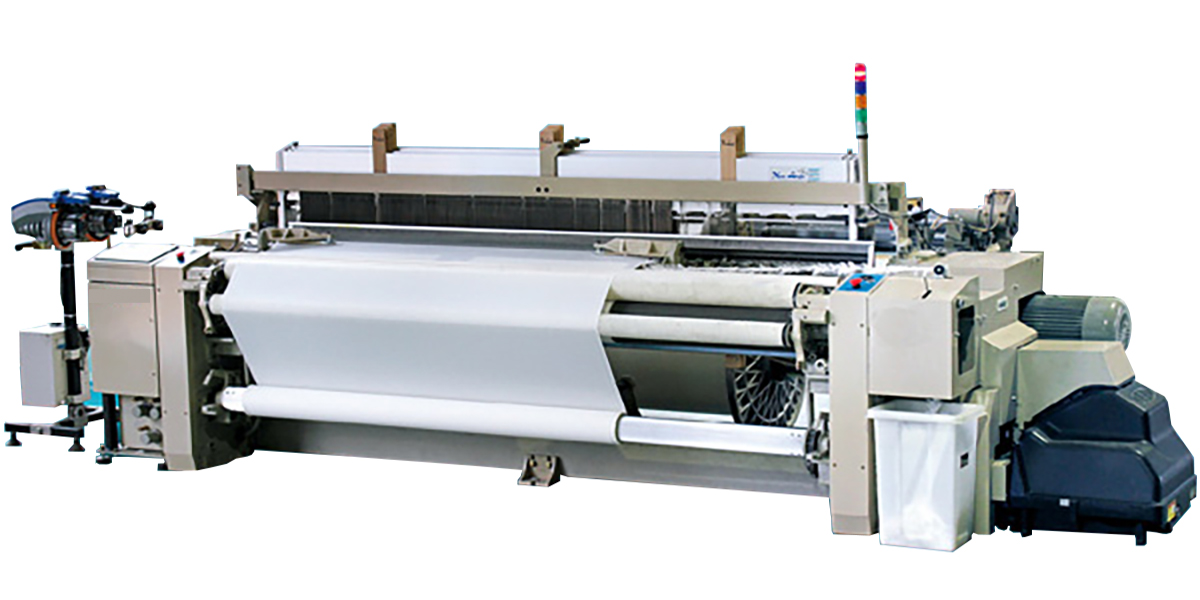

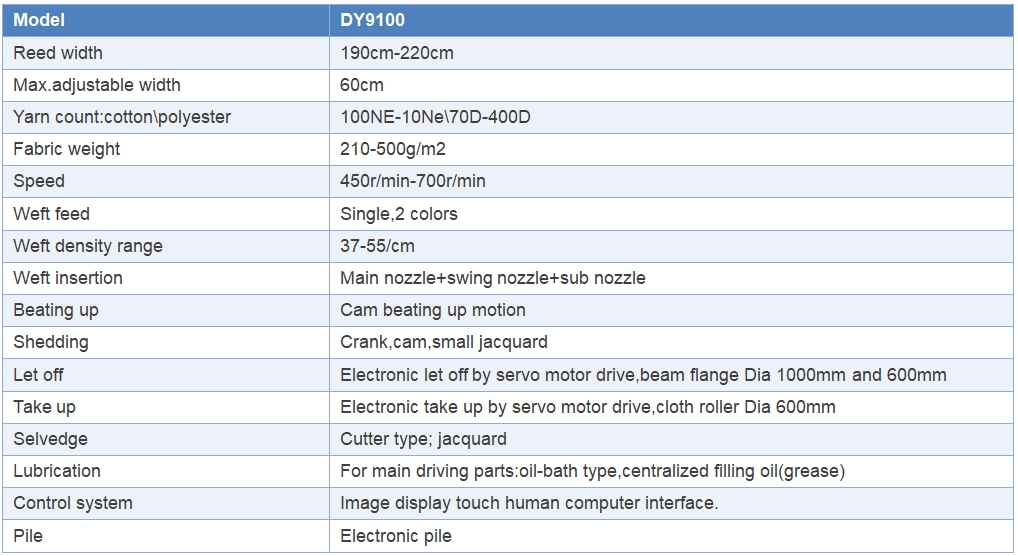

DY9100 High Speed Velvet Fabrics Airjet Looms

The velvet fabrics airjet looms apply to the strong loom structure base on picanol body and staubli dobby shedding , which be used in velvet industry, such as velvet 9000, velvet 5000 etc.the solid beating shaft and multiple auxiliary supporting and balanced beating systems improve the stability of the loom at high speed running condition,using the main air nozzle and swing nozzle and sub nozzle with high speed weft insertion.this model has higher production efficiency and the lowest air energy consumption and smooth velvet fabrics.