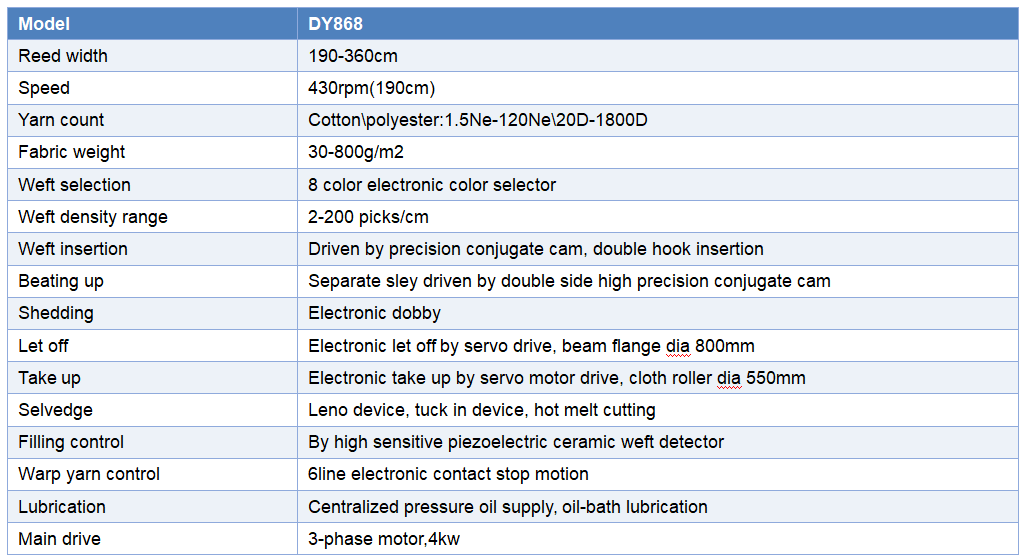

The normal reed width is from 190 cm – 360 cm

Effective reed width: 0-40 cam taken away from the nominal reed width value.

Maximum weft insertion rate: 1200 m/min.

1.Electronic let off with servo motor,warp tension setting can be turned into an instruction through the tension sensor plus a comprehensive treatment by CPU to drive the let off serve system,to ensure constant warp tension from the full to the empty warp beam.

2.The high integration microprocessor, support speed more than 400 rpm,pattern data can be conveniently copy by USB from the computer to the control system.

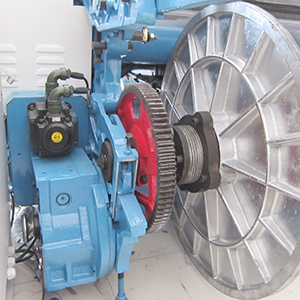

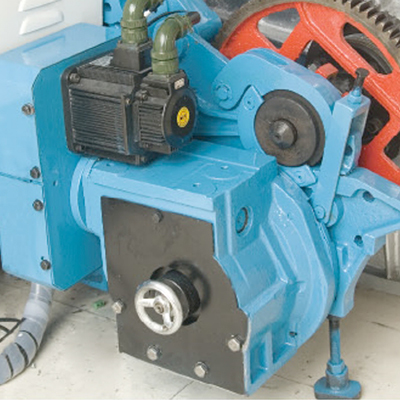

3.Weft insertion: two side conjugate cam through a connecting rod transmission gear sector,the turning gear drive the rapier wheel precision weft insertion. Beating:conjugation by high precision beating cam,drive strong short sley, to ensure the beating up force for weaving high density fabric and heavy fabric.

4.The double beam hardening off,negative stationary device,not only suitable for light to heavy fabric,but also can improve the fabric quality,electronic let off equipped with compensation system,effectively prevent fabric start mark.

5.Electronic take up with servo,weft density through the control panel to set, according to different weft density alternating weaving, to meet a variety of different fabrics weft density requirements.

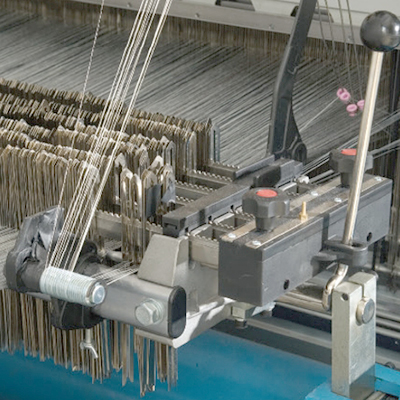

6.Electronic 8 color selector by electronic control cam driven, suitable for various weft yarn,color selection program computer programming,USB input, can also input by control panel

7.Can be equipped with variety shedding device. Dobby and jacquard.all shedding mechanism can be equipped with auto finding mechanism,auto pick finding,ETU, ELO,which can effectively prevent the start mark.

8.Stop motion can quickly find the broken warp position,thus improving the weaving efficiency.